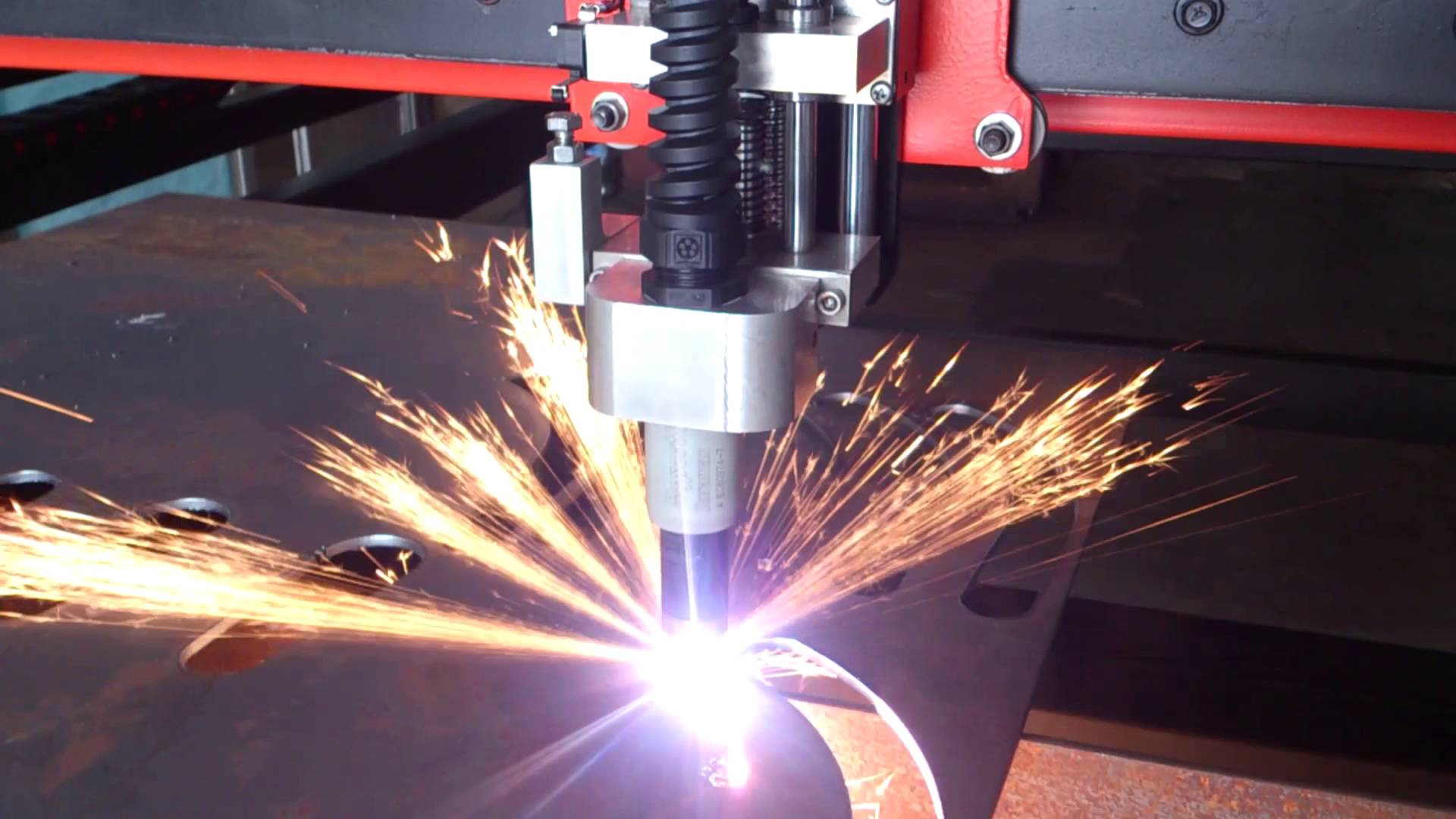

What is plasma cutting?

The cutting process through various electrically conductive objects by using hot plasma accelerated jets is called plasma cutting. We can use a plasma torch that includes stainless steel, brass, copper, and steel for this purpose. The fabrication shops and automotive repairs use such techniques in their work. The cost of it is meager as it involves high-speed working and precision cuts with great ease.

Many industrial CNC users and applications use such methods, and you will also find hobbyist shops involving in such activities. The restoration and scrapping industry is also famous for using such things in their work. You will require face shields and eye protection for doing such work.

Working of a plasma cutter

The plasma cutters send electric arcs using gas, which passes through a constricted opening. These gases can be nitrogen, oxygen, and argon.

- Plasma cutters elevate the gas temperature to enter the 4th matter state, which is the plasma. The metal cut is the circuit’s part. That is why the conductivity through electricity causes the transfer of the arc to its work.

- The nozzle will open the gas to pass through them and cause a squeeze moment at a faster rate. It looks like the air is passing through the carburetor venturi. The gas, due to its speed, will cut the metal that is in a molten state. It is directed towards the perimeter in their cutting region to provide a shield to these cuts.

- Touching on the torch tip is also a brilliant method for creating sparks. It will use starting circuits with high frequency for the work. But these methods will no be effective with automated or CNC cutting.

- CNC cutters are also brilliant products that automate the shape of the production process. They use tape with little holes in them for offering the instructions for the primitive computers.

- You can use the CNC units to run the burning machines. Many computers adapt to such things. It offers the cut quality and speed in production as other methods. Here you can arrange various shapes on your screen by cutting them automatically. You will not have to touch these materials also. It lets the users program their pauses for better piercing, and you can scale down and up within few seconds. It allows to set the accelerations and also decelerate at various corners. With the units of the electric eye, the other functions are not possible.

Safety concerns

The best plasma cutters will also require many safety concerns. Experts recommend using lens shade to prevent yourself from eye damage. You will also want an apron, jacket, and leather gloves to prevent yourself from hot metals burns and sparks. It is best to work with them in an area clear from flammable liquids and materials. It can cause a fire with great ease and increase the risk factors. The sparks can also fly up to 5 feet distance. So take necessary safety precautions to avoid risk and damage from such things. That way, you can do your work without any complication.